Sida funded REFOREST students and their lecturers during an excursion in Southern Highlands of Tanzania (Photo credit: QGEC staff)

Tanzania being a middle-income country, is focusing more on industrialization to spur economic development. Forestry sector is one of the key areas for promoting sustainable socio-economic transformation. Mainland Tanzania has a total forest cover of 54.4% of the total land area of 88.3 million hectares. Much as deforestation rate is very high in Tanzania at 469,420 ha/year, the country has put in mechanism of establishing tree plantations to reduce pressure on the remaining natural forest areas. Currently, the total tree plantation area is 553,040 ha, of which approximately 250,000 ha are in the Southern Highlands. The major species planted are Pinus patula, Eucalyptus species and Acacia mearnsii which provides raw material for the majority of wood-based industries. Importantly, 64% of the industrial plantations are owned by smallholder farmers with 36% being owned by the government and private commercial tree companies. Among the government forest plantations, Sao Hill forest plantation is the largest plantation covering a total area of 135,903.35 ha.

The REFOREST Programme (hosted at Sokoine University of Agriculture), organized a field excursion, which took place from 1st – 8th July, 2021. The purpose of the excursion was to expose the Sida funded REFORESTProgramme PhD students to the different aspects of forest based value chains within the Southern Highlands of Tanzania. Based on the green field projects visited, the following observations were made;

1. Commercial forest plantations for wood based industries

Pine, Eucalyptus and Acacia mearnsii are the major sources of raw material for wood based industries in Tanzania.

a) Sao Hill Forest plantation in Mafinga

This is the largest plantation covering a total area of 135,903.35 ha in Tanzania. Due to the increasing wood demand in Tanzania which is projected to move from 79.6 – 95.92 million m3 by 2025, the government through Tanzanian Forest Service Agency (TFS) has embarked on raising quality plantations to meet the high demand. Research and Development in improved tree germplasm is on-going so as to enhance the productivity of the tree crops. The plantation is managed in accordance with the Forest Management Plan which is always developed for a period of 5 years. Major plantation activities that are ongoing include, nursey operations, establishment of new sites, maintenance of immature young crops, pruning and thinning, harvesting of mature stands. Forest protection is conducted diligently through awareness creation among the local communities, fire prevention measures are in place including heavy duty firefighting trucks, and well-trained fire standby crews supported with hand held equipment and fire outlook towers.

At Sao Hill forest plantation, sustainable harvesting based on the allowable cut is being implemented annually. Most of the concessions are allocated to local buyers for logs and sawn timber processing. Also, some compartments with Pine logs are supplied to Mufindi Paper Mill for production of paper as they wait for the maturity of their own planted forests.

Top view of part of division one at Sao hill forest plantation (photo by Alberto Manhica)

Sao Hill tree nursery and established Pinus patula plantation (Photo by: Alberto Manhica)

In order to diversify the revenue generated from the plantation, management has allowed ATY- a Chinese based company to tap pine resin from mature crop which is about to be harvested within 2-3 years. The resin tapping started in 2017/2018 on trial basis and TFS in collaboration with the College of Forestry Wildlife and Tourism (at SUA) is yet to ascertain the effect of resin tapping on the wood properties. Resin tapping provides new opportunities for business and research.For example,tapping methods used but also determining optimum crop age has to be researched.

Resin extraction from mature Pinus patula trees (photo by Daniel Obua)

b) Kiwira forest plantation at Mbeya

Kiwira forest plantation with an area of 2,820 ha is located in Mbeya region of Tanzania and it is managed by TFS. The forest is unique in the sense that Pinus patula has adapted to the local environment and some compartments were actually allowed to undergo natural regeneration after being clear felled some time back. The challenge with natural regeneration of trees in plantations is that, it is difficult to maintain the right spacing, tree density per unit area and uniformity of the regeneration. It requires a lot of manipulation in terms of reducing the `number of seedlings to the required density per unit area and transplanting of seedlings to areas with few regenerants. From the outlook, the area which underwent natural regeneration appears to have accumulated also very high stand volume. Therefore, it is important that applied research be conducted to evaluate cost effectiveness of using natural regeneration (seed rain) versus use of nursery seedlings to restore harvested areas.

Presently, Tanzania Forestry Research Institute (TAFORI) is undertaking species trials to test the performance of Pinus maximinoi in order to add it to the list of main species to be planted in southern highlands. It will also be advisable to monitor these pine species with the increasing distance from the pine stand matrix because they have been reported to be invasive (especially P. elliottii) in certain location due to their ability to regenerate through seeds and sprouts.

Nursery operations and young Pine plantation established by TFS at Kiwira Forest Plantation (Photo by Daniel Obua)

Naturally regenerated forest at Kiwira plantation (Photo by: Lemma Tikki)

2. Technical services support to the forestry sector

a) Forest Development Trust (FDT): Is an independent Tanzanian institution established in 2013 by the Gatsby Charitable Foundation with a long-term vision for strengthening the capacity of the locals for commercial forestry development. The outstanding technical services offered includes research and development, training and support of tree growers association to enhance their forest plantation productivity and market development with enabling environments for inclusive, competitive and resilient business models in wood products for maximum profitability.

In a bid to change small scale tree growers’ attitude and perceptions towards profitable commercial forest plantations, FDT established demonstration plots at Kisolanza farm in 2014. The demonstration plots are used to showcase best management practices to improve forest productivity and profitability. The technologies under demonstration includes spacing, germplasms, suitable eucalyptus clones to be adopted, intensive vs non application of silvicultural operations demo trials, pests and disease management and integrated fire management and a number of research activities. All the demos are strategically located along the Iringa-Mbeya highway for ease of visibility by a range of forestry stakeholders and ease of accessibility to training of tree growers.

FDT demonstration plot of different Eucalyptus spp at Kisolanza (Photo credits: Alberto Manhica)

FDT demonstration and experimental plots of different Eucalyptus and Pine species at Kisolanza (Photo credits: Alberto Manhica)

b) Forestry And Wood Industries Training Centre (FWITC): The centre was established in 2017 with the mission to empower the tree growers in areas of tree nurseries establishment and management, seed orchard establishment, forestry inventory practices and marketing of forest products as well as training experts and entrepreneurs in wood processing including timber, briquetting (charcoal and sawdust), pole production systems, furniture making and saw doctoring. The training centre has been accredited by the Vocational Education and Training Authority (VETA) to offer certificate in vocational training education programs for wood processing and forestry attendants.

Furniture making and Densified briquettes produced from sawdust (Photo credits: Daniel Obua)

Sawdoctoring training workshop and electric timber kiln at FWITC (Photo by David Kissa)

High quality seedlings produced using soilless culture (Cocopeat substrate) and furniture production (Photo by Daniel Obua)

3. Tree Growers Association in Southern Highlands

Tree growers association in Southern highlands is comprised of the local tree growers and they form part of the bigger Tanzania Tree Growers Associations Union (TTGAU). Most of the members are small scale tree growers with planted areas ranging from 2-10 ha and they are supported with technical services from FDT and FWITC to boost the quality of the wood from their plantations in order to become competitive in the wood-based industry. The platform is being used as an advocacy for strengthen the capacity of small-scale tree growers to have better access to markets that offers premium prices. The association takes care of the gender representation in the community especially the youth and women when it comes to allocation of village forest land for tree growing. Overtime, the small-scale tree growers have benefited from sales of wood products and this has helped to improve their livelihoods.

Members of smallholders Tree Growers Association in Nyombo Village with REFOREST Programme studentsand SUA instructors; and timber trade from small scale tree growers (Photo by: Daniel Obua)

4. Selected wood based industries visited in Southern Highlands of Tanzania

a) Mufindi Paper Mills Ltd (MPM)

The paper mill factory was established by the Tanzanian Government in 1979 with the main support from Swedish International Development Cooperation Agency and partial contribution from the World Bank and German Development Bank. It became fully operational in 1986 with a capacity of 60,000 tons of pulp and paper production from soft wood produced in the Sao Hill forest plantation. The paper produced from Mufindi meets both the domestic and regional paper demand. Currently, the paper is exported to Uganda, Rwanda, Kenya, and Mozambique.

The booming paper industry coupled with the availability of wood material supply from their own plantations and Sao Hill Forest Plantation is encouraging the MPM management to expand on their business through introduction of more production lines which is expected to produce variety of paper to meet the increasing market demand. The company intends to be outsourcing Acacia mearnsii wood from TANWAT to increase the quality of the pulp.

Wood chips at MPM ready for paper making (Photo by: Gaudance Nshimwe)

Pulp and paper production at Mufindi Paper Mills Ltd, Iringa region (Photo by: Gaudence Nishimwe)

b) East Africa Born Wood Limited

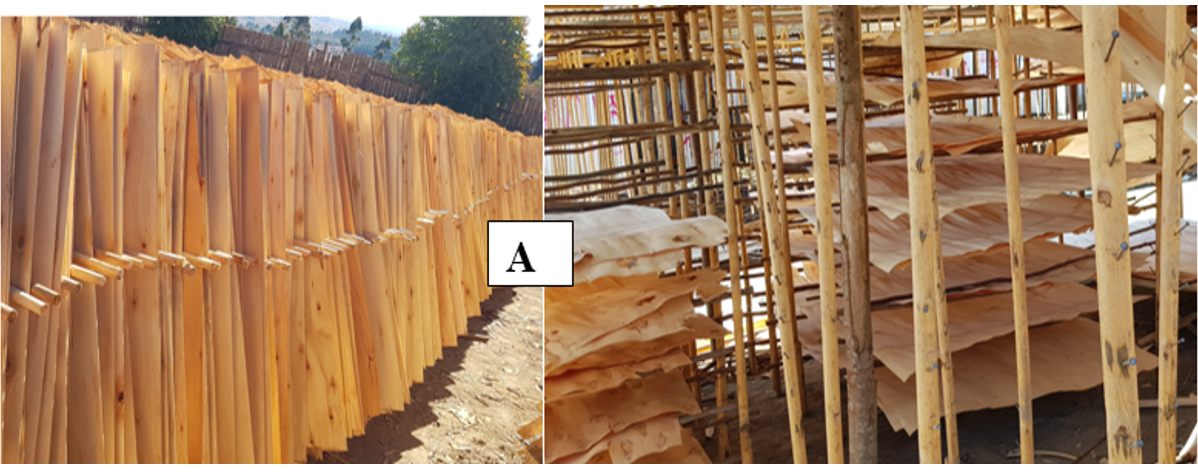

We visited this company which is producing plywood in Iringa. The company uses simple equipment that are movable and it uses the new emerging technology of veneer production from small diameter logs. This is done for both eucalyptus and pines but in different production lines. The wood materials for veneer production is outsourced from the local small scale tree growers. During the plywood production, we were informed of the key processes that has to be undertaken to ensure quality. The key processes include; cutting to size, pealing, drying, grading and joining (binding) but also time, pressure application are very important to the quality of the final product.

Air drying (A), Sizing (B), Grading (C) and Sticking (D) at East Africa Born Wood Limited

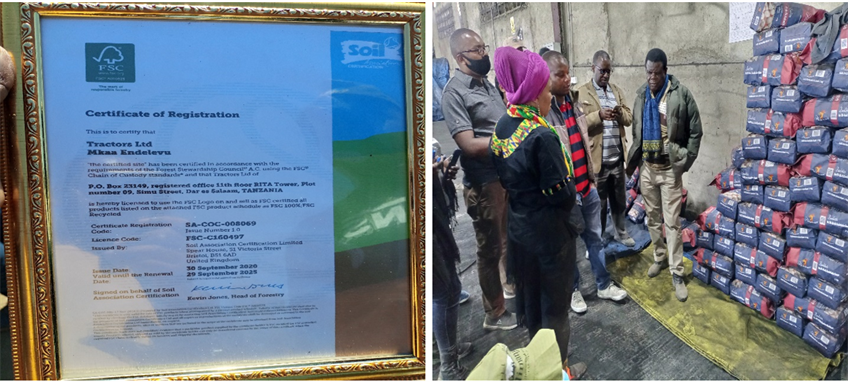

c) Tractors Company Ltd (TCL)

TCL is a local company producing briquettes, wood vinegar, wood tar, and tar from the pyrolysis of sawdust collected as residues from wood processing industries (sawmills) around Mafinga. From the sawdust, the yield is 25% Char, 25% Wood Vinegar, and 50% (Wood tar & Gas). The company also uses off-cuts (wood wastes) from the plywood factories (East Africa Born Wood Company), the off-cuts are carbonized using the Brazilian kilns. The charcoal produced is crushed into powder and mixed with cassava as a binder to produce briquettes of different sizes and shapes. The company is FSC certified and they are compliant on socio-economic and environmental principles as outlined in the FSC guidelines. The wood vinegar is exported to Australia meanwhile wood tar is sold and used for pole treatment by domestic industries. Most of the charcoal briquettes are currently exported to German and USA as they plan to expand their market niche into other European countries.

Waste wood processing and briquette packed in sacks at Tractor Company Ltd, Iringa region (Photo by: David Kissa)

Briquette produced from waste for export to German (Photo by: David Kissa)

d) New Forest Company Ltd (NFC)

The NFC is owned by foreign investors and it operates in the East African Region (Uganda, Rwanda, and Tanzania). In Tanzania, the company was established to produce timber and treated utility poles. Presently, the company is carrying out both vertical and horizontal integration to achieve its primary objective. Within the vertical integration, it acquired 8,435 ha of land from the government of Tanzania whereby 4,855 ha is for commercial forest plantation (Pine-2,755 ha and Eucalyptus-2,100 ha), and the rest is for conservation. As a measure of implementing its horizontal integration, the company purchases poles from government plantations, medium and small scale tree growers to produce utility poles from its installed 150,000 capacity pole treatment plant. Currently, it has managed to be producing approximately 40,000 poles per year as they wait for their own eucalyptus crop to mature.

Electric Poles treatment center and treated poles (Photo by: Daniel Obua)

e) Qwihaya General Enterprises Company Ltd (QGEC)

QGEC is privately owned company by a Tanzania nationals and their main purpose is utility pole treatment but as a way of diversifying the enterprise, they also perform sawmilling, furniture production, plywood manufacture and transportation on small scale. For the meantime, QGEC is outsourcing its wood materials from Sao Hill forest plantation and other private/ small tree growers as they wait for their planted forests at Mufindi and Kigoma to mature. To reduce costs of pole treatment, QGEC prepare its own Copper Chromium Arsenate (CCA) to meet their installed pole treatment plant capacities. Overall, QGEC has production capacity of 400,000 treated poles per year in the different treatment plants located at Iringa, Njombe and Kibaha. The utility poles are consumed domestically for rural electrification expansion by TANESCO and Rural Energy Agency (REA).

QGEC office and utility pole yard (Photo by: Scolastica Ntalikwa)

f) Tanganyika Wattle Company (TANWAT), Njombe Region

TANWAT Company is located in Njombe region of Tanzania and it was established in 1947 specifically for production of tannin from Acacia mearnsii (Black wattle). Tannin is the name given to a mixture of oligomeric polyphenolic compounds found in the barks of (Acacia mearnsii), quebracho wood (Schinopsis batansae), sweet chestnut (Castanea sativa), and pine (Pinus radiata and Pinus nigra) trees. Tannin is widely used in the leather, pharmaceutical, and mining industries. The global market of tannin was estimated to be at 1.4 million tonnes and it is expected to grow at an estimated rate of 5.5% over the period 2020-2027. Black wattle tannin is mainly manufactured in Brazil, South Africa, India, and Tanzania. Currently, TANWAT has 15,560 ha of forest plantations with 50% composed of black wattle, 38% Pines spp (Pinus patula and Pinus elliotii) and 12% Eucalyptus spp (Eucalyptus grandis, Eucalyptus saligna, Eucalyptus citriodora, and Eucalyptus cloeziana). Tannin is only produced from the bark extracts of black wattle trees. At TANWAT, pines are used for the production of timber and plywood whereas eucalyptus are used for utility pole production and as a source of bioenergy for generation of heat and electricity. The excess electricity produced is sold to the national grid through TANESCO.

The optimum tree age for high tannin resin production is between 10 -12 years. On average, each tree at maturity can yield approximately 33 kgs of high quality barks and the bark contains 30-45% (dry basis) high-quality tannins. Tannin extraction is done by use of hot water and it lasts for about 6 hours. TANWAT produces about 7,000 tons of tannins and 90% is exported to Italy, United Kingdom, Pakistan, India, Kenya and Egypt. The 10% is locally used by both formal and informal domestic leather industries.

Harvested black wattle bark for tannin processing and packed tannin for export (Photo by: Lemma Tikki)

As way of corporate social responsibility, the company allows local communities to collect (free of charge) the debarked wood of black wattle for charcoal production and the branches for fuelwood. The largest amount of this charcoal is consumed in many of the cities in Tanzania including Dar es salaam. This contributes to improve the biofuel availability in the country /region but most importantly, it is a source of revenue to all the local communities who are interested in charcoal production.

Peeled black wattle wood used for production of charcoal by the local communities (Photo by: David Kissa)

Lessons learned

Tanzania is moving towards a vibrant forestry sector due to the strong partnerships between the government institutions, private sector, local authorities and development partners. The existing collaboration among the private and public institutions and other stakeholders has helped to reduce the inefficiencies and the challenges within the forestry sector. Involvement of various stakeholders in addressing the challenges along the forestry value chains has made Tanzania forestry sector to become an attractive investment area and a promising contributor to the national economy. Importantly, REFOREST PhD Students learnt the following key lessons that can be benchmarked by other countries in the region in order to transform forestry sector into an engine for socio-economic transformation;

1. In Tanzania, tree productivity and profitability has been hampered for long period due to availability of mostly inferior germplasm materials and poor implementation of silvicultural practices by the large section of the tree growers (small-scale growers). To address the challenges, FDT in collaboration with other stakeholders have brought improved breeding populations of tree species into the country to improve the quality of germplasm but also reduce costs of purchasing seedlings by tree growers. Equally, FDT has established an open on-farm demonstration trials of best and poor silvicultural practices that tree growers can learn from and be able to make informed decision for enhancing the productivity of their tree plantations.

2. Concentrating tree plantations in defined locations as for the case of southern highlands in Tanzania has huge advantages especially for small scale tree growers ranging from access to better extension services, ease of attracting investment in wood based industries, sustainable utilisation of other wood wastes and improvement in the overall standard of living for the local communities as a result of increased disposable incomes of individuals.

3. Natural regeneration of Pines especially Pinus patula can be a possible option of reducing establishment costs especially for areas undergoing large scale restorations. Thus, it is imperative to note that, forest landscape restoration will require such knowledge of adaptive natural regeneration capacities of trees in order to boost the implementation of the Bonn challenge and other regional forest restoration initiatives.

4. The introduction of modern but simpler technologies for utilizing small diameter trees in veneer production creates a more attractive business opportunity for small scale tree growers who are unable to wait for the long maturity periods of some tree products (utility poles and timber). The most important lesson learnt is the formation of groups of small scale growers that has increased their capacity to favourably compete within the existing forest product markets in the country.

5. The involvement of local communities in forest management activities including harvesting of the mature trees through allocation of considerable percentage of the felling coupes has helped reduced the negative impacts of local communities on the forest resources. A case in point is “Sao Hill Forest Plantation” with over 135,000 ha of planted forests scattered within the enclaves inhabiting many communities. This poses threat of illegal harvesting and fire outbreaks but TFS has managed to effectively collaborate with the local communities and thus, in regard there is reduced incidence of fires and illegal logging. Forthrightly, local communities are rewarded with other benefits including construction of health facilities, distribution of desks to schools and construction school dormitories among other things.

6. Finally, gender consideration is key in the forestry sector development as witnessed by many women and youth employed along the value chains from nursery operations, tree establishment and harvesting in Tanzania. Hence, there is need for countries to train more women in forestry at all levels to help remove the disparity and inequality along the value chains. REFOREST Programme is a good example on this. Below is a picture of REFOREST PhD students at SUA and it depicts the level of affirmative actions to be undertaken to have women empowered as so to realise their key contribution towards sustainable management of forest enterprises.

Women in the Sida funded REFOREST Programme: Group photo of female PhD forestry students together with Prof Susana Agustino, the Principal CFWT during the excursion (Photo by Lemma Tikki)

Prepared by REFOREST Programme Students